At Keller, we offer cost-effective and environmentally-beneficial soil remediation solutions to reduce contaminants to levels which are suitable for use without environmental risks or danger to health.

Increasing land shortage is driving a need to use more brownfield and marginal land often requiring groundwater and soil remediation to reduce contaminants. Keller is the ideal partner for remediation projects, offering the optimal solution to make contaminated land suitable for re-use.

Challenges we can help solve

- Soil contamination in urban areas and former industrial sites where manufacturing, industrial dumping, and waste disposal may have occurred

- Soil contamination below the surface due to leaks from buried tanks, pipes, or landfill

- Contamination that is seeping through the soil into groundwater or being carried to nearby land and waterways in rainwater

Approaches to soil remediation and prevention of contamination

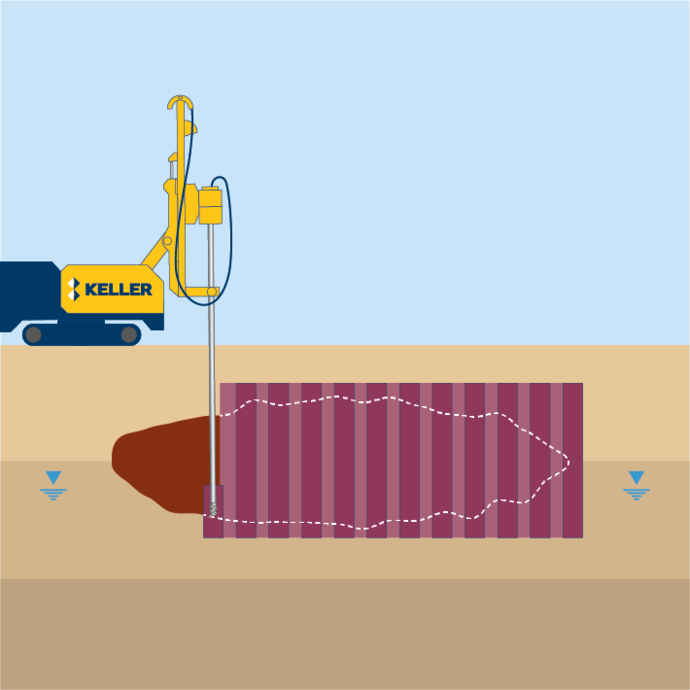

On-site treatment

This in-situ chemical oxidation (ISCO) converts contaminated soils into non-hazardous soils by introducing remediating agents. It is particularly useful for remediating contaminants in difficult to access areas, for example, beneath buildings.

We can use a number of different techniques to introduce different remediating agents into the soil. In an innovative extension of the Jet grouting / Soilcrete® process, Halocrete involves adding a chemical reactant to the jet grouting slurry mix, strengthening the ground with soil-cement columns while, at the same time, degrading the contaminant in situ.

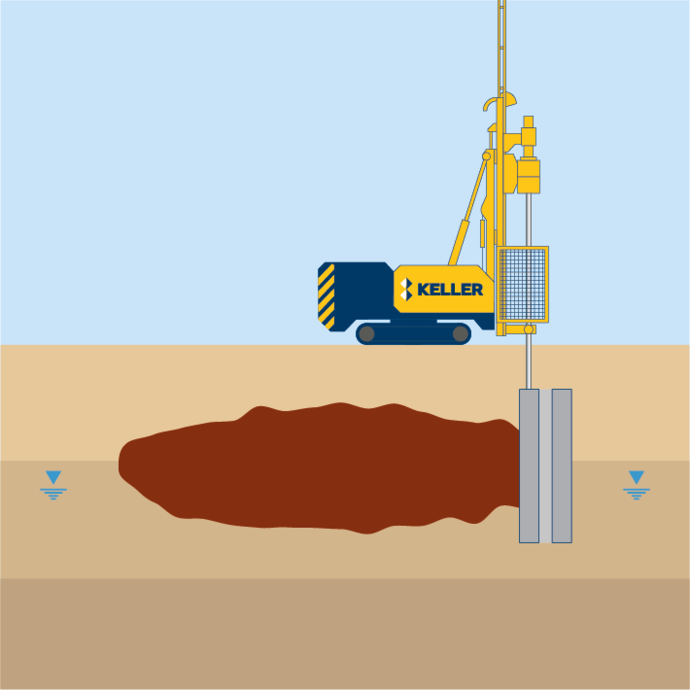

Removal

This involves digging up and removal of contaminated soil from a site for above-ground treatment or disposal.

When the contamination is too deep or too close to existing structures, we use bored piles to enable excavation without the need for horizontal support.

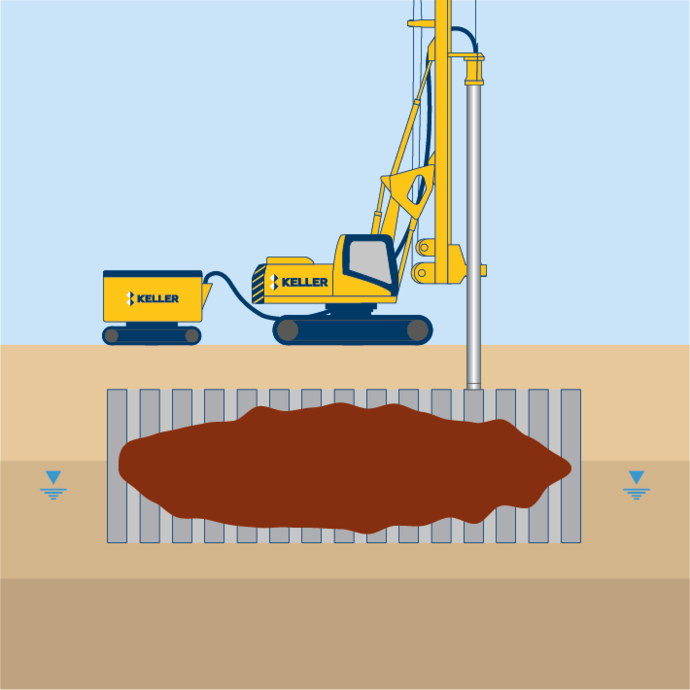

Stabilisation

Binders are mixed with the in-situ soil to transform it into a new, solid, non-leachable material, effectively locking contaminants in place.

This technique can also be used to improve the geotechnical competency of the ground, increasing resistance and lowering permeability to make it more suitable to build on.

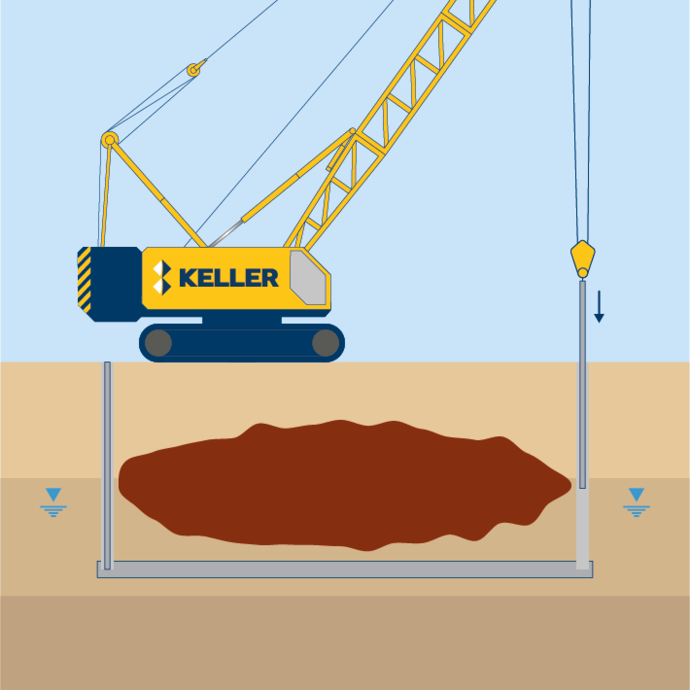

Containment

This involves the creation of an impermeable barrier to contain contaminants, eliminating the need for its costly removal and disposal.

Benefits

- Multiple solutions for different contaminants including heavy metals, mineral oils, PAH (Polycyclic Aromated Hydrocarbons) and chlorinated hydrocarbons

- Minimal impact on people and existing structures

- Compliance with environmental regulations

- Efficient with minimal waste