Helical piles, also known as screw piles, are constructed using steel shafts with helical flights (helix/helices) of various sizes to suit the site specific ground conditions.

Common uses

Process

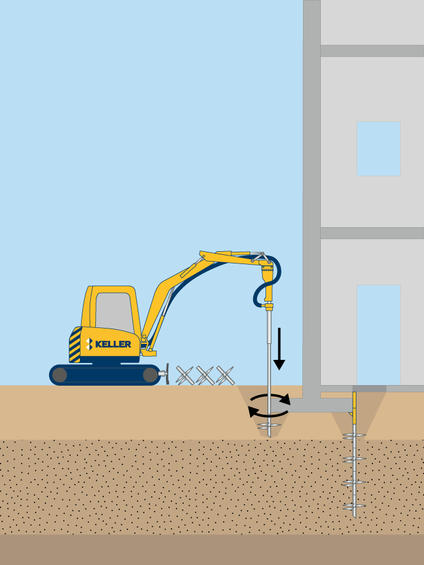

Piles are generally installed using standard tracked or wheeled excavators with a torque motor attachment which monitors the torque achieved during installation to verify the design.

Helical Piles are advanced to the predetermined (design) bearing strata by rotating the steel shafts with the torque motor attached to the excavator plant/rig. Multiple steel sections are connected via a bolted connection and sections are added to complete the total pile depth.

Helical flights strategically designed along the shaft penetrate the soil without augering, displacing the soil,whilst the torque is carefully monitored as the pile advances. The final torque reading is taken over the last 1m of advancement to ensure the pile is achieving the required design before terminating at the correct datum level.

Helical Piles are able to restrain unfactored (SWL) axial loads of up to 300kN, uplift loads of up to 200kN subject to the ground conditions and lateral loads of up to 25kN. Higher lateral forces can be restrained with the addition of a concrete collar to the top of the pile head.

A detailed understanding of the subsurface conditions (especially soil strata type, strata levels and strength (SPT ‘N’ Values) to depth is necessary to properly interpret the required design and torque capacities.

On completion, the top of the pile can be connected in various ways to the structure by a direct steel flange plate connection or plate/rebar connection to concrete.

Advantages

Quality assurance

Keller is able call upon a wealth of knowledge and experience to offer and successfully deliver the optimum solution. Static load testing can be done to monitor and confirm performance and that the required settlement criteria is met.