Ductile piles are a deep foundation method using the displacement technique with prefabricated piles made of ductile cast iron available in 118 mm and 170 mm diameters with different wall thickness.

Common uses

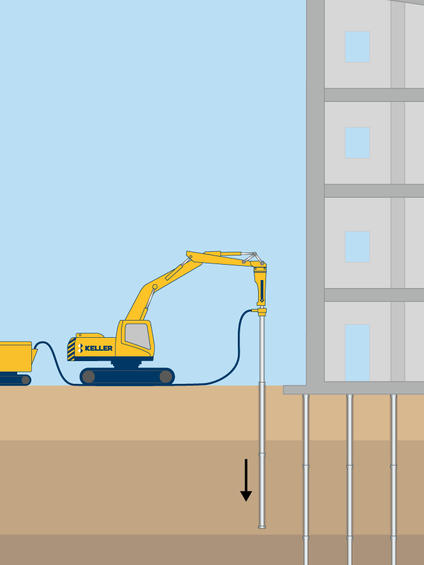

Process

A driving shoe is placed after preparation of the working platform and pre excavation of the footings. The ductile pipes are about 5 metres long and formed with a shock sleeve. The first pipe is installed into the driving shoe and then one pipe after the other stuck together and driven down until driving criteria is reached.

If there are grouted piles to perform, the first pipe is cut close to the driving shoe so that the mortar is able to full fill the free space between the pipe and the soil performed by a larger diameter of the driving shoe. Diameters from 200 mm up to 370 mm are normal depending on the soil conditions

Directly after installing the piles, the pile heads designed as steel load spreading plates are placed on the ductile pipes.

Advantages

Quality assurance

Keller is very experienced in installing ductile iron piles, having installing several million linear metres over time.

The load capacity of each pile can be controlled with driving criteria and the optimum pile length achieved. Our driving criteria and back analysis can self-validate the pile load capacity. A static load test called the Hay Proof System has the added value of obtaining the skin friction and toe resistance values of the pile load capacity.